We are an innovative company committed to sustainability

Our mission is to transform natural waste into biodegradable materials for the manufacturing of environmentally valuable products using various techniques, including additive manufacturing. We focus on the circular economy, aiming to reduce environmental impact and create useful, eco-friendly products. Through emerging technologies and sustainable practices, we aspire to revolutionize the biodegradable materials market. Our resulting materials offer diverse mechanical and plastic properties for use in sectors like construction, fine arts, 3D printing, medicine, packaging, DIY, and many more.

The formaché material has been derived in two different formats:

Moldable dough

Moderable and moldable product for the creation of three-dimensional volumes, with properties of plasticity, flexibility and great resistance to compression.

- resistance

- Lightness 95%

- Flexibility 35%

Injectable paste

Injectable product thanks to its combination with emulsified air in micro bubbles, which gives it greater lightness and modifies its state making it more fluid.

- resistance

- Lightness 95%

- Flexibility 35%

DISCOVER

The

ULTRARESISTANT

first modelable paste

from

paper fibers

Model and Go!

Modelable

Plastic sensation close to clay for modeling and molding.

SOSTENIBLE

Manufactured in a sustainable way from raw materials that respect the environment.

RESISITENTE

Reduce the steps of the sculptural process. Model and go!

NO TÓXICO

Non-toxic components for handling without gloves.

SECA AL AIRE

Forge at room temperature without the need for cooking.

ECONOMIC

All its components are accessible in the market and therefore are affordable for all budgets.

Possibilities of the Material

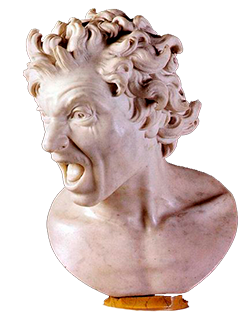

PLASTIC ARTS

Express your creative ideas using our pastas to build sculptures without the need for complex structures.

BUILDING

Construct complex surfaces from material shaping. Use it also as a cementing material.

3D PRINT

Create complex structures by adapting cartridges from the most viscous material to your 3D printer.

DIY

Repair, paste, finish or seal endless surfaces and materials. A quick and effective solution to thousands of handicaps.

PACKAGING

Make customized packaging for your products in an economical and safe way to be the number one in logistics.

MEDICAL

Its immediacy of setting and low toxicity offers the opportunity to take care of you and your loved ones.

CONTINUOUS DEVELOPMENT OF TECHNOLOGIES

MATERIAL TESTING

DIFFERENT COMBINATIONS OF MATERIAL

TYPOLOGIES

%

R & D + I

RESEARCH

BACKGROUND

Why have so few pieces of value arrived until our days made in papier-mâché? Is there a way to give resistance to this material to make it durable over time?

The purpose of the patented invention has been to obtain a moldable plastic material, light and resistant.

With regard to papier mâché, FORMACHÉ Molding Paste gives it greater mechanical strength and lightness, and an excellent plasticity for molding.

OUR PARTNERS

Thanks to the collaborating entities, we continue to create new lines of research.

YOU ARE ABOUT TO MAKE A DIFFERENCE with a

NEW MATERIAL